ECKSTEIN

PRODUCT DESIGN / OCT—DEC 2023

eckstein was created as part of a course I took in the fifth semester. Over a period of eight weeks we of worked in a group of four to develop and produce a product made from industrial waste material.

During our research, we came across clinker bricks that were produced and glazed for a farmhouse kitchen around 60 years ago.

Right from the start, our vision was to turn the clinker bricks into egg cups that could ideally also be used for other practical purposes.

PROCESS

STYLEBOARD

IDEA AND CONCEPT

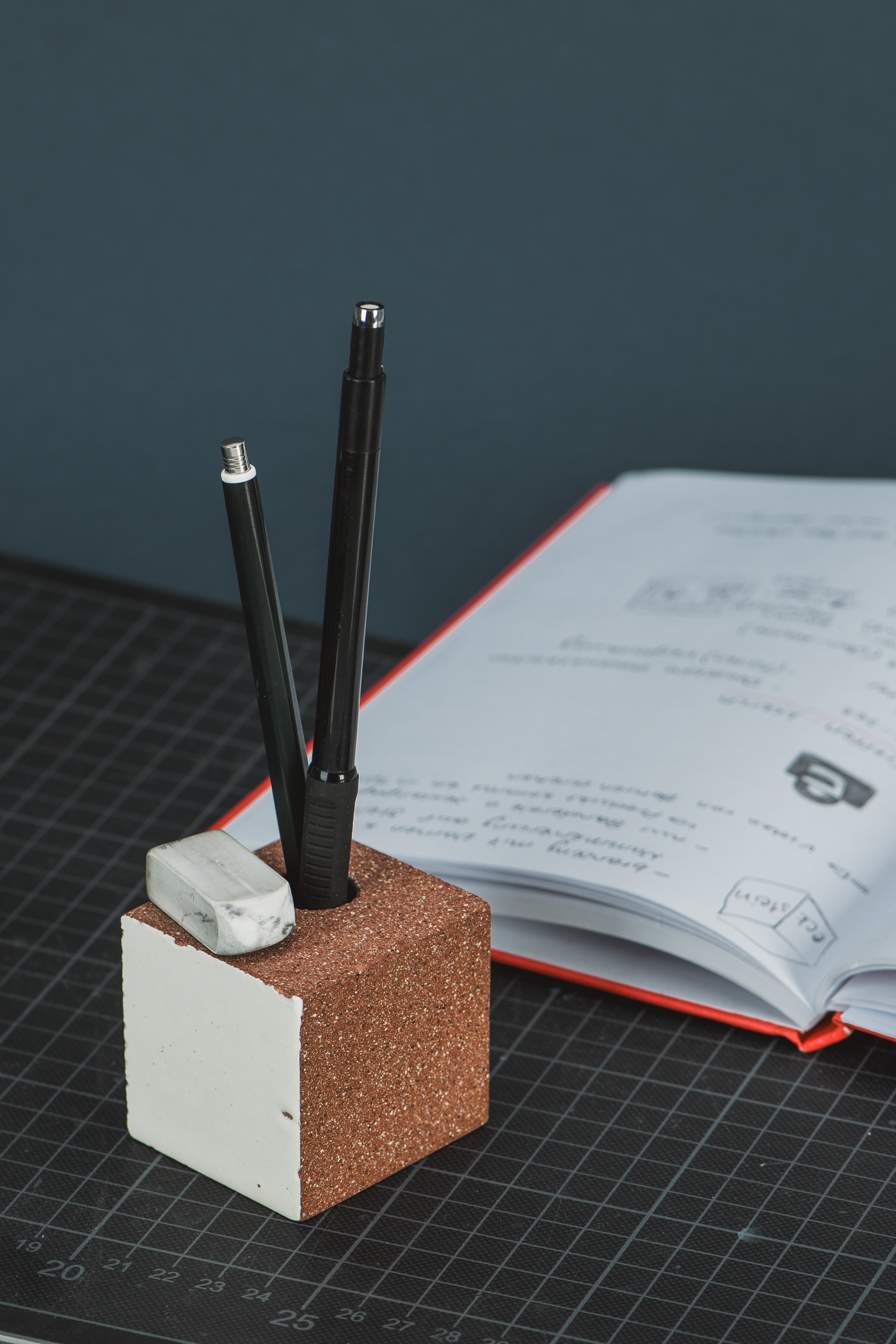

Extend the existing hole to create a multifunctional product that can be used as a candle holder, egg cup, toothbrush holder or even more.

PRODUCTION

The production of the products underwent about five steps: First, we removed the remains of the glaze from the tops and bottoms of the stones. Then we assembled the stones into sets of four and sanded them so that their sides and heights had the same dimensions.

The stones were then drilled individually. During the process, the blunted drill bit required repeated sharpening to achieve a clean result and avoid damaging the stones.

Finally, all stones were finely sanded with a diamond sanding block and two wet sanding passes to ensure a comfortable hand feel and no sharp edges. All sanding processes required manual work.

We put the stones in the oven at 100°C for about an hour to dry them.

The production did not always went smoothly and was very time-consuming. We had to continuously adapt the process and overcome obstacles such as stubborn glaze residue or blunt drills. Each stone required individual treatment in order to maintain the high quality of our end products and to be able to sell them to our customers with a good conscience.

In the end, we completed 26 sets of four and 13 singles.

PRODUCTS AND PACKAGING